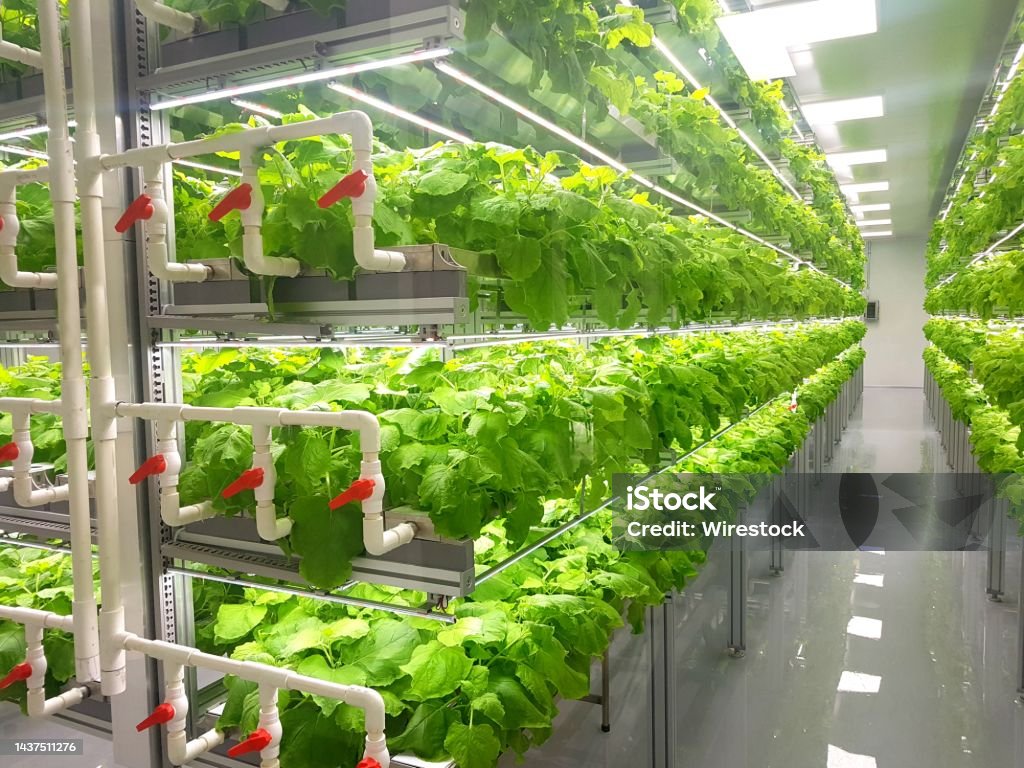

Indoor farming operations consist of greenhouses, cannabis grow facilities, and vertical farms. Greenhouses tend to be more traditional with their use of soil as a growing medium, and transparent windows to allow natural light to reach the plants. Meanwhile, cannabis grow facilities and vertical farms are most commonly “hydroponic,” meaning they use different growing mediums instead of soil. They also tend to use artificial light in place of sunlight for their plants. This in tandem with highly regulated irrigation translates to a concept called Controlled Environment Agriculture (CEA).

CEA poses unique challenges when it comes to designing HVAC systems. Both cannabis grow facilities and vertical farms are susceptible to government regulations regarding food safety, air quality, and air changes per hour. The environment also must adhere to particular air conditions in order to optimize plant growth. For example, cannabis crop production is typically separated into four stages: (1) seeding, (2) vegetation, (3) early flowering, and (4) late flowering. For each of these stages, the plants have specific temperature and humidity specifications.

The consequences of poor HVAC design in CEA are far greater than general discomfort.

Humidity: If humidity surpasses acceptable levels for too long, the plants will be susceptible to mold and mildew, resulting in lost product and/or raise food safety concerns for the entire facility. If the air is too dry, the plants will compensate by absorbing more water from their roots which can lead to nutrient burn. Nutrient burn can hinder their ability to absorb light and can cause a loss in leaf mass.

Temperature: If growing conditions are too hot or too cold, it can limit photosynthesis and the growth of the plant, thus reducing its yield.

In addition to strict setpoints, the load analysis of these environments is unlike typical commercial buildings. Artificial lighting results in substantial sensible loads, while the irrigation, run-off, and evapotranspiration make up major latent loads. At the same time, the evapotranspiration has a cooling effect on the system, providing a “negative” sensible load. While the design and risks of HVAC in commercial indoor agriculture pose a great challenge, the end result of a controlled environment allows for protection from weather, year-round crop production, and an opportunity for impressive crop yields.

Plants on vertical farms grow with led lights. Vertical farming is sustainable agriculture for future food.