Chemical Project Examples

Miller Engineering has collected a large library of historical publications related to the government, industry, medical community, and the scientific community which have resulted in comprehensive historical summaries for substances listed below:

- Acetone

-

Arsenic

-

Asbestos

-

Benzene

-

n-Butyl Acetate

- Diacetyl (popcorn butter flavor)

-

o-Dichlorobenzene

- Lead in Paint

-

Methanol

-

n-Methyl-2-Pyrrolidone

-

Methyl Ethyl Ketone

-

Methylene Chloride

-

Perchloroethylene (dry cleaning solvents)

- Tobacco

-

Trichloroethylene

-

Vinyl Chloride (intermediary chemical in PVC production)

- Welding Rod and Asbestos

Diacetyl Exposures

Miller Engineering has been involved with many cases regarding exposure to diacetyl, also known as popcorn butter flavoring. We evaluate material safety data sheets (MSDS) and compare them to the applicable standards relevant to the time period of exposure. We also commonly investigate factors such as sufficient ventilation and adequate personal protective equipment (PPE), especially respirators.

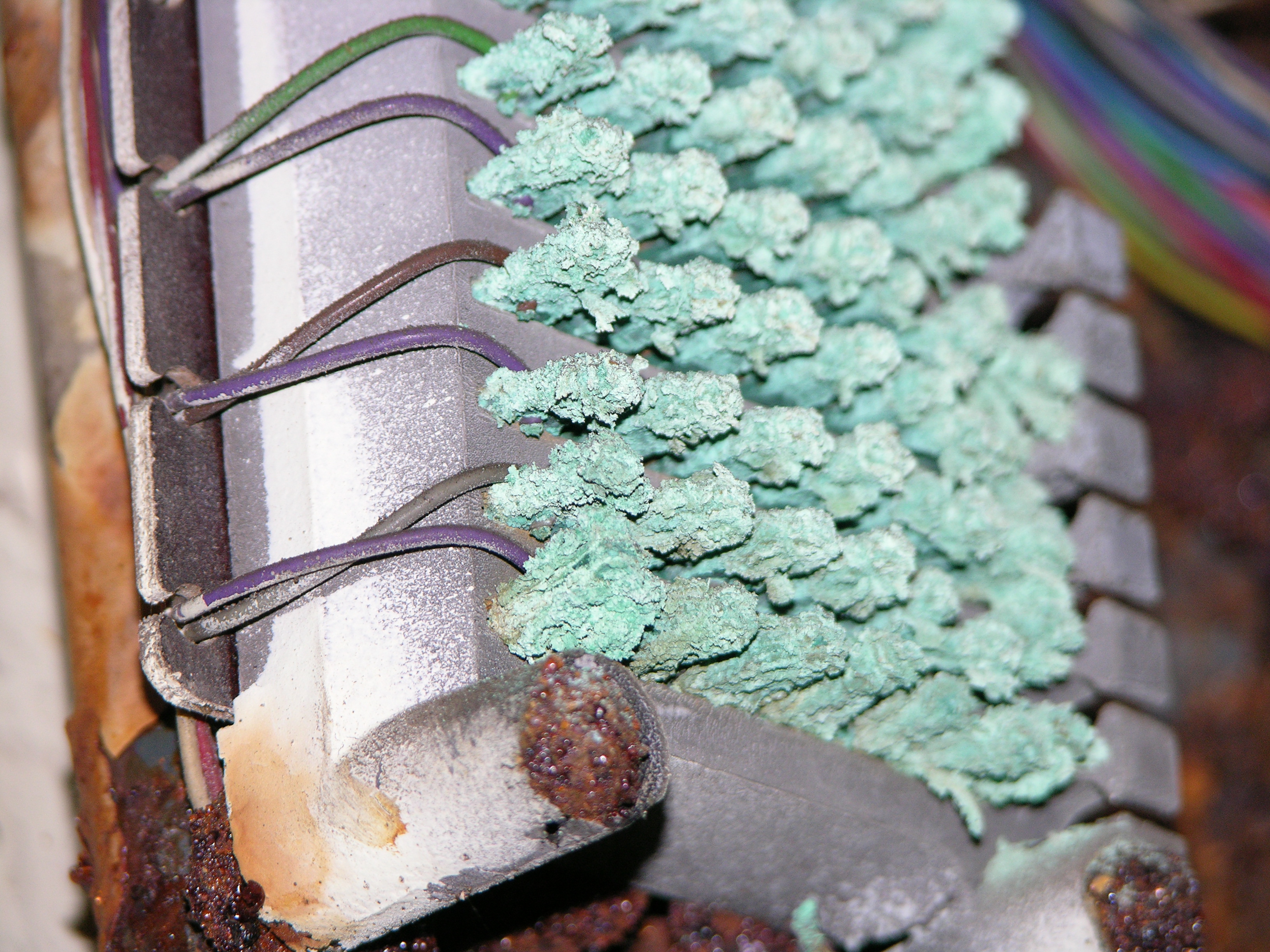

Severe Corrosion Investigation

Miller Engineering performed site visits and conducted research to investigate extensive property damage that resulted from severe corrosion. A chemical company used a building to store extreme oxidizing agents (dimethylhydantoin and bromo-chloro-dimethylhydantoin) in powder form. We assessed several factors that contributed to the accelerated corrosion, including excess humidity, a roof leak, and airborne particles. In short, the company had failed to adequately contain and control its stored chemicals.

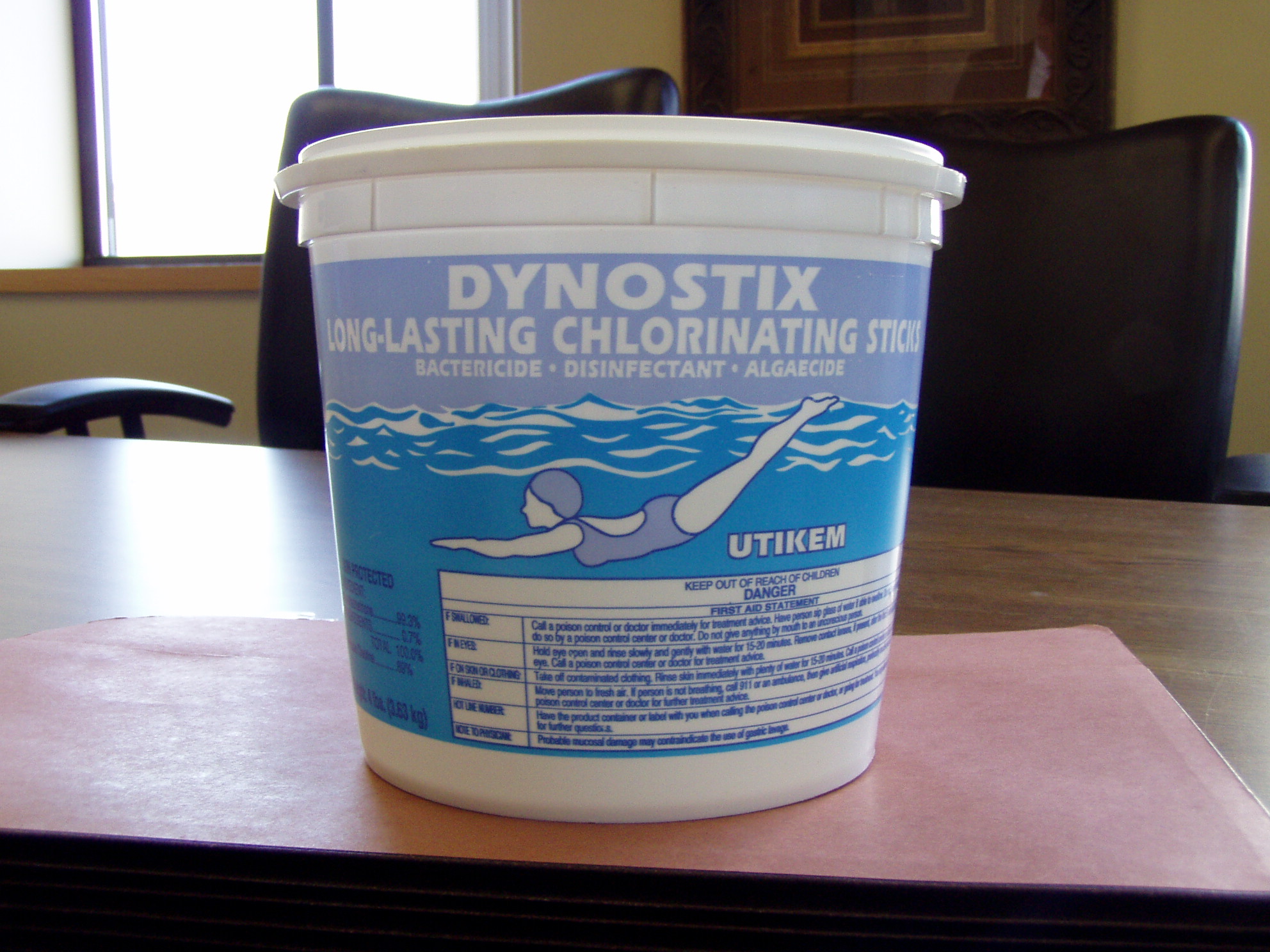

Chemical Labeling Design

Our experts are often retained to evaluate the adequacy of chemical product labeling.

In one case, we assessed a label that appears on a product containing a chemical in the “chlorinated isocyanurates” family. We investigated toxicity levels, relevant EPA standards, and first aid requirements. We determined that the product label meets all requirements and adequately precautions users against inhalation health hazards.

In other cases, when labels are identified as insufficient, Miller Engineering often recommends and implements design changes that propel product labeling well beyond the minimum acceptable standards.